Craven Fawcett Unveils its Cutting-Edge Innovations for the Heavy Clay Industry

Craven Fawcett, a global pioneer in the design and manufacture of clay preparation machinery and spare parts, has introduced new innovations into two of its most widely utilised machines in the heavy clay and ceramics industries.

The first is Craven Fawcett's state-of-the-art Fine Roller Mill which features a range of technological advancements including a common auto re-set mechanism for optimised spares holding. It's roll scrapers are now arranged in sections and feature replaceable wear tips.

With this new improved model, all bearing housing is bolt-on, split and external to the main machine body, allowing for easy bearing maintenance, including access for removal and replacement of components. The machine also includes anti-vibration mounts and detachable electrical control on roll turning.

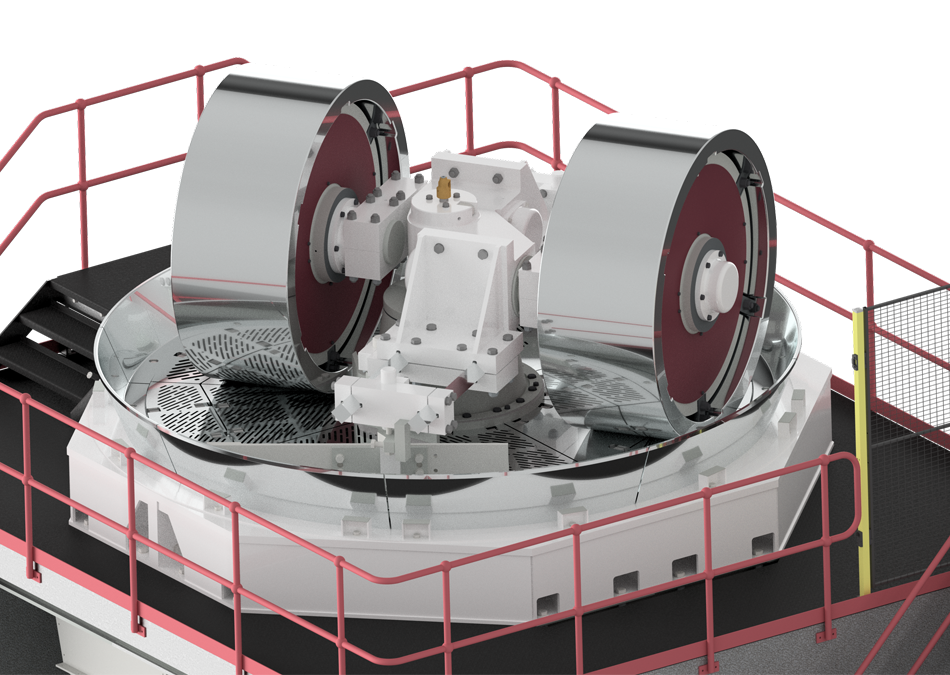

The second machine to be upgraded is the Delta 45 Wet Pan Mill, which has undergone several enhancements including an inching facility and split shield section for improved and easy access during maintenance. In addition, it now features segmented and reversible scraper wear tips for greater longevity and hear-wearing cast steel grids with taper slots that allow for a longer life and increased output. Additionally, the machine now features a variable speed underdriven hydraulic drive for additional flexibility.

Both machines have been designed and manufactured at Craven Fawcett's facility in Wakefield, West Yorkshire and were recently supplied to the first net zero brick facility in the UK at Ibstock's Atlas site in the West Midlands.

Glynn Dixon, Contracts Manager at Craven Fawcett, stated, "We are continuously developing our machinery to address the increading demands of the brick production and clayworking industries. These two machines are truly cutting-edge and were the ideal selection for Ibstock at their brand-new flagship facility."

Craven Fawcett is the UK's leading manufacturer of clay preparation machinery and a division of Group Rhodes.

The company has a 180-year history of designing and supplying equipment for the heavy ceramics sector. This includes a full portfolio of clay preparation machinery ranging from Box Feeders and Grinding Mills through to Mixers and Extruders. With a dedicated in-house team of highly trained and experienced service engineers, the company provides short-noticed repair and maintenance services for clay preparation equipment in the field as well as full turnkey solutions.

If you want to find out more information regarding Craven Fawcett, please visit the website https://www.cravenfawcett.co.uk/, call us at 0 (44) 1924 375444. Alternatively, follow the company on LinkedIn.