Mechanical presses are ideal for continuous running fully interlocked with automatic feeding, especially when blanking/piercing at high speed where tonnage is required near the bottom of stroke.

The combined wealth of knowledge of the Rhodes experienced design team, enables Joseph Rhodes to offer bespoke machinery of 'all' sizes and tonnage ratings.

The Rhodes ranges of Mechanical Presses include:

DS1 DOUBLE SIDED PRESSES - Single point double sided presses available in nine models from 40 - 400 tonnes. The DS steel frame is designed to maintain accurate tool alignment under maximum load and provides great strength, rigidity and maximum accessibility to the die space.

DS2 DOUBLE SIDED PRESSES - Designed specifically with two point suspension to provide a larger working bed area suitable for either wide single tools or a gang of smaller tools. The two point suspension ensures even distribution of the nominal tonnage and helps to accommodate any offset loading on large progression tools. The seven models on this range vary from 80-400 tonnes.

SAXON MECHANICAL PRESSES - Available in 'C-frame' or Double Sided construction and with either Geared or Ungeared drive, the SAXON range offers features for every production application.

SAXON C - Frame presses have been designed to provide excellent all round visibility making them the perfect machine tool for performing second operation, hand fed work. The fully integrated all steel frame has been designed to occupy the minimum amount of floor space, whilst affording maximum access to the tooling area.

The SAXON range of Double Sided presses caters for the most popular tonnages in this market sector. The double sided steel frame construction is designed to maintain accurate tooling alignment under maximum load conditions. Class leading linear deflection characteristics make this machine an ideal progression tool press.

RH Presses Single or Two Point suspension C-Frame presses from 25 – 250 Tonnes. Internationally regarded as the ‘quality press of choice’, the RH range boasts low frame deflection and long die life derived from the heavy press construction and massively ribbed one-piece frame. Made to order, these presses are incorporated into project critical applications worldwide. RM Presses – Designed as a low cost versatile machine, RM Presses are the backbone of many production lines. The ranges are available with model ratings from 25 to 100 tonnes. Presses up to and including 80 tonnes can be supplied inclinable if required. The RM 100 press is supplied with a fixed frame upright as standard or permanently inclined to special order.

Design Features of Rhodes Mechanical Presses include:

- A Rhodes Hydraulic Overload device located under the ball screw seating in order to prevent a major overload.

- Full CNC controls can be fitted to monitor all the press functions, and provide additional auxiliary outputs.

- Hydraulic tool clamping and a Quick Tool Change carriage can be fitted to provide 'Just-In-Time' benefits.

- Optional Safety Light Curtain and the Rhodes patented G.E.A.R mechanism, (which have proven to increase productivity by up to 30%, when manually feeding)

- High performance, low inertia combined friction clutch and brake units allow a fast single stroking rate with the minimum of heat build-up.

- Massive press construction utilising quality materials and generous bearing surfaces guarantee minimum deflection and longer die life.

- Ergonomically designed to occupy the minimum of floor space.

- Geared or ungeared models available.

- Manual or fully motorised slide adjustment.

- Pneumatic Slide Balance to guarantee smoothness of operation and extended die and bearing life at all speeds.

- Optional Variable Stroke.

DS1 Range

| DS1 Model | 40 | 60 | 80 | 100 | 160 | 200 | 250 | 315 | 400 |

|---|---|---|---|---|---|---|---|---|---|

| Rating (Tonnes) | 40 | 60 | 80 | 100 | 160 | 200 | 250 | 315 | 400 |

| Speed continous (Standard) - spm | 140 or 160 | 140 or 60 | 120 or 60 | 120 or 50 | 120 or 45 | 30 | 30 | 30 | 30 |

| Standard fixed stroke (mm) | 114 | 114 | 127 | 152 | 152 | 152 | 203 | 203 | 203 |

| standard variable stroke (mm) | 25 to 114 | 25 to 114 | 25 to 127 | 25 to 152 | 25 to 152 | 25 to 152 | 50 to 203 | 50 to 203 | 50 to 203 |

| Slide adjustment (mm) | 76 | 89 | 89 | 102 | 102 | 102 | 102 | 102 | 102 |

| Bedplate to slide at half stroke - Slide adjustment up (mm) | 279 | 305 | 355 | 406 | 406 | 508 | 609 | 609 | 609 |

| Thickness of bedplate (mm) | 63 | 76 | 89 | 89 | 102 | 114 | 127 | 140 | 152 |

| Area of bedplate (mm) | 609 x 609 | 762 x 685 | 914 x 762 | 1016 x 838 | 1092 x 914 | 1168 x 1016 | 1168 x 1016 | 1219 x 1067 | 1219 x 1067 |

| Area of slide face (mm) | 381 x 317 | 508 x 381 | 609 x 508 | 736 x 559 | 914 x 635 | 965 x 660 | 965 x 762 | 1016 x 813 | 1016 x 914 |

| Hole in bed (mm) | 355 x 254 | 406 x 279 | 444 x 305 | 508 x 406 | 559 x 482 | 609 x 559 | 660 x 609 | 762 x 609 | 762 x 609 |

| Hole in side frames (width x height) (mm) | 279 x 305 | 279 x 330 | 355 x 457 | 355 x 533 | 432 x 533 | 432 x 559 | 432 x 609 | 508 x 609 | 508 x 609 |

| Approximate weight - tonnes | 5 | 7.5 | 9 | 12 | 16 | 25 | 28 | 32 | 39 |

| Overall Diemnsions (mm) Length x width x height | 1600 x 1524 x 2819 | 1905 x 1829 x 3200 | 2210 x 2134 x 3658 | 2362 x 2210 x 3810 | 2515 x 2206 x 3962 | 3048 x 2348 x 4267 | 3200 x 2515 x 4343 | 3658 x 2591 x 4420 | 4115 x 2667 x 4495 |

| Hydraulic overload safeguard rating (mm) | 12 | 12 | 12 | 12 | 12 | 19 | 19 | 19 | 19 |

| Motor H.P. | 5 | 10 | 10 | 15 or 10 | 20 or 15 | 20 | 25 | 30 | 40 |

Where two speeds are given, the higher speed is for Direct Flywheel Driven model. Higher speed models are also available.

DS2 Range

| DS2 Model | 80 | 100 | 160 | 200 | 250 | 315 | 400 |

|---|---|---|---|---|---|---|---|

| Rating (Tonnes) | 80 | 100 | 160 | 200 | 250 | 315 | 400 |

| Speed continous (Standard) - spm | 120 or 60 | 120 or 50 | 120 or 45 | 30 | 30 | 30 | 30 |

| Standard fixed stroke (mm) | 152 | 203 | 152 | 254 | 254 | 254 | 254 |

| standard variable stroke (mm) | 25 to 127 | 51 to 152 | 51 to 152 | 51 to 203 | 51 to 203 | 51 to 203 | 51 to 203 |

| Slide adjustment (mm) | 102 | 102 | 102 | 102 | 102 | 127 | 152 |

| Bedplate to slide at half stroke - Slide adjustment up (mm) | 381 | 432 | 432 | 508 | 508 | 559 | 559 |

| Thickness of bedplate (mm) | 102 | 114 | 114 | 140 | 140 | 152 | 203 |

| Area of slide face (mm) | 1016 x 914 | 1168 x 914 | 1321 x 1016 | 1676 x 1067 | 1676 x 1067 | 1829 x 1067 | 1829 x 1067 |

| Hole in bed (mm) | 711 x 432 | 864 x 432 | 1016 x 533 | 1118 x 559 | 1118 x 559 | 1219 x 559 | 1219 x 559 |

| Hole in side frames (width x height) (mm) | 330 x 305 | 330 x 305 | 457 x 305 | 457 x 305 | 458 x 305 | 508 x 305 | 508 x 305 |

| Approximate weight - tonnes | 12 | 17.5 | 21 | 30 | 32 | 38 | 50 |

| Overall Diemnsions (mm) Length x width x height | 2590 x 1676 x 3429 | 3125 x 1676 x 3429 | 3277 x 2286 x 4039 | 3658 x 2438 x 4267 | 3658 x 2515 x 4267 | 4267 x 2591 x 4343 | 4420 x 2895 x 4420 |

| Hydraulic overload safeguard rating (mm) | 12 | 12 | 12 | 19 | 19 | 19 | 19 |

| Motor H.P. | 10 | 15 or 10 | 20 or 15 | 20 | 25 | 30 | 40 |

Where two speeds are given, the higher speed is for Direct Flywheel Driven model. Higher speed models are also available.

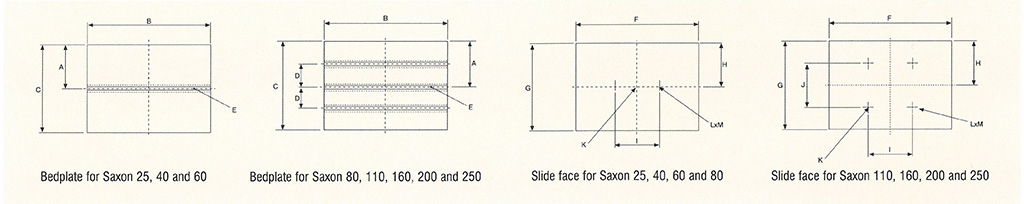

SAXON Un-Geared Presses

| Press Model | 25 | 40 | 60 | 80 | 110 |

|---|---|---|---|---|---|

| Rating (tonnes) | 25 | 40 | 60 | 80 | 110 |

| Continous operation (strokes/minute) | 165 | 165 | 165 | 165 | 120 |

| Maximum fixed stroke (mm) | 100 | 100 | 120 | 120 | 125 |

| Stroke length standard (mm) | 25 | 25 | 25 | 25 | 25 |

| Slide adjustment (mm) | 60 | 60 | 80 | 80 | 80 |

| Motor power (KW) | 3 | 4 | 7.5 | 7.5 | 11 |

| Bedplate to slide SDAU (max fixed stroke) (mm) | 240 | 240 | 300 | 300 | 375 |

| Bedplate to slide SDAU (standard stroke) (mm) | 275 | 275 | 345 | 345 | 425 |

| Thickness of bedplate (mm) | 90 | 90 | 90 | 100 | 120 |

| A Bedplate Dimensions (mm) | 200 | 220 | 275 | 275 | 300 |

| B ('C' Frame) L - R (mm) | 630 | 850 | 1000 | 1000 | 1250 |

| C ('C' Frame) F - B (mm) | 400 | 440 | 550 | 550 | 600 |

| B (Double Sided) L - R (mm) | 600 | 740 | 830 | 900 | 970 |

| C (Double Sided) F - B (mm) | 400 | 440 | 550 | 550 | 600 |

| D (mm) | 137.5 | 150 | |||

| E Slots for T-Bolt (Dia) (mm) | 20 | 20 | 20 | 26 | 26 |

| F L - R (mm) | 400 | 580 | 750 | 750 | 850 |

| G F - B (mm) | 250 | 340 | 420 | 420 | 500 |

| H (mm) | 125 | 170 | 210 | 210 | 250 |

| I (mm) | 150 | 240 | 275 | 275 | 305 |

| J Slide Face Dimensions (mm) | J' Dimensions available on request | ||||

| K Dia (mm) | 50 | 50 | 50 | 50 | 50 |

| L Dia (mm) | 14 | 18 | 18 | 18 | 28 |

| M Deep (mm) | Thro | Thro | Thro | Thro | Thro |

| Distance between plates (double sided) (mm) | 700 | 840 | 930 | 1000 | 1070 |

| Passage through back (C frame) (mm) | 360 | 440 | 520 | 520 | 670 |

| Throat Depth (C frame) (mm) | 205 | 225 | 280 | 280 | 310 |

| Overall Height (mm) | 2800 | 2800 | 2900 | 2900 | 3200 |

| Front to back (mm) | 1850 | 1900 | 1950 | 1950 | 2000 |

| Left to right (mm) | 780 | 1000 | 1150 | 1150 | 1400 |

| Floor to bed (mm) | 735 | 735 | 735 | 735 | 735 |

| Approximate weight (tonnes) | 3 | 4 | 6 | 8 | 12 |

Additional tonnage peciffications available on request

SAXON Geared Presses

| Press Model | 25 | 40 | 60 | 80 | 110 | 160 | 200 | 250 |

|---|---|---|---|---|---|---|---|---|

| Rating (tonnes) | 25 | 40 | 60 | 80 | 110 | 160 | 200 | 250 |

| Continous operation (strokes/minute) | 80 | 80 | 70 | 60 | 60 | 50 | 50 | 50 |

| Maximum fixed stroke (mm) | 100 | 100 | 120 | 120 | 180 | 180 | 200 | 200 |

| Stroke length standard (mm) | 50 | 50 | 60 | 60 | 90 | 90 | 100 | 100 |

| Slide adjustment (mm) | 60 | 60 | 80 | 80 | 80 | 100 | 120 | 120 |

| Motor power (KW) | 2.2 | 4 | 5.5 | 7.5 | 7.5 | 11 | 15 | 18.5 |

| Bedplate to slide SDAU (max fixed stroke) (mm) | 240 | 240 | 300 | 300 | 350 | 400 | 450 | 450 |

| Bedplate to slide SDAU (standard stroke) (mm) | 265 | 265 | 330 | 330 | 395 | 445 | 500 | 500 |

| Thickness of bedplate (mm) | 90 | 90 | 90 | 100 | 120 | 150 | 200 | 200 |

| A Bedplate Dimensions (mm) | 200 | 220 | 275 | 275 | 300 | 400 | 420 | 420 |

| B ('C' Frame) L - R (mm) | 630 | 850 | 1000 | 1000 | 1250 | 1250 | 1400 | 1500 |

| C ('C' Frame) F - B (mm) | 400 | 440 | 550 | 550 | 600 | 800 | 840 | 840 |

| B (Double Sided) L - R (mm) | 600 | 740 | 830 | 900 | 970 | 1100 | 1150 | 1200 |

| C (Double Sided) F - B (mm) | 400 | 440 | 550 | 550 | 600 | 800 | 840 | 840 |

| D (mm) | 137.5 | 150 | 200 | 210 | 210 | |||

| E Slots for T-Bolt (Dia) (mm) | 20 | 20 | 20 | 26 | 26 | 26 | 26 | 26 |

| F L - R (mm) | 400 | 580 | 750 | 750 | 850 | 850 | 950 | 950 |

| G F - B (mm) | 250 | 340 | 420 | 420 | 500 | 500 | 700 | 700 |

| H (mm) | 125 | 170 | 210 | 210 | 250 | 250 | 350 | 350 |

| I (mm) | 150 | 240 | 275 | 275 | 305 | 305 | 375 | 375 |

| J Slide Face Dimensions (mm) | J' Dimensions available on request | |||||||

| K Dia (mm) | 50 | 50 | 50 | 50 | 50 | 50 | 50 | 50 |

| L Dia (mm) | 14 | 18 | 18 | 18 | 28 | 28 | 28 | 28 |

| M Deep (mm) | Thro | Thro | Thro | Thro | Thro | Thro | Thro | Thro |

| Distance between plates (double sided) (mm) | 700 | 840 | 930 | 1000 | 1070 | 1190 | 1250 | 1300 |

| Passage through back (C frame) (mm) | 360 | 440 | 520 | 520 | 670 | 670 | 750 | 800 |

| Throat Depth (C frame) (mm) | 205 | 225 | 280 | 280 | 310 | 410 | 430 | 430 |

| Overall Height (mm) | 2800 | 2800 | 2900 | 2900 | 3200 | 3700 | 4100 | 4500 |

| Front to back (mm) | 1850 | 1900 | 1950 | 1950 | 2000 | 2000 | 2500 | 2500 |

| Left to right (mm) | 780 | 1000 | 1150 | 1150 | 1400 | 1400 | 1550 | 1650 |

| Floor to bed (mm) | 735 | 735 | 735 | 735 | 735 | 735 | 735 | 735 |

| Approximate weight (tonnes) | 3 | 4 | 6 | 8 | 12 | 16 | 22 | 25 |

Additional tonnage specifications available on request

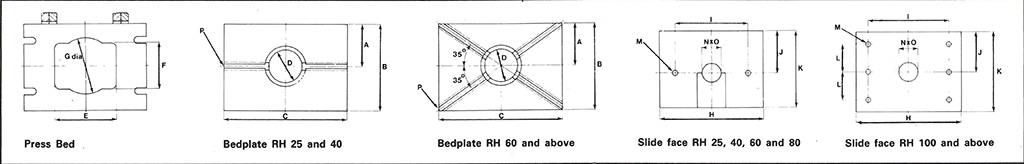

RH Range

| Press Model | RH25 | RH40 | RH60 | RH80 | RH100 | RH160 | RH200 | RH250 |

|---|---|---|---|---|---|---|---|---|

| Press type (Direct Driven/ Geared) | DD | DD / GRD | DD / GRD | DD / GRD | DD / GRD | GRD | GRD | GRD |

| Rating (Tonnes) | 25 | 40 | 60 | 80 | 100 | 160 | 200 | 250 |

| Continous opertion strokes/minute | 165 | 165 / 65 | 165 / 60 | 165 / 60 | 115 / 50 | 45 | 33 | 30 |

| Clutch engagements/ minute | 80 | 80 / 46 | 80 / 42 | 80 / 42 | 75 / 35 | 32 | 23 | 21 |

| Maximum fixed stroke (mm) | 102 | 114 | 114 | 127 | 152 | 152 | 152 | 203 |

| Standard variable stroke (mm) | 13 - 102 | 25 - 114 | 25 - 114 | 25 - 127 | 25 - 152 | 25 - 152 | 25 - 152 | 51 - 203 |

| Slide adjustmentc (mm) | 51 | 76 | 89 | 89 | 102 | 102 | 102 | 102 |

| Motor (HP) | 3 | 5 | 10 | 10 | 15 / 10. | 15 | 20 | 25 |

| Bedplate to slide at half stroke adjustment up (mm) | 241 | 279 | 305 | 356 | 406 | 406 | 508 | 610 |

| Thickness of bedplate (mm) | 64 | 64 | 76 | 89 | 89 | 102 | 114 | 140 |

| A Bedplate (mm) | 210 | 235 | 267 | 286 | 343 | 375 | 457 | 457 |

| B Bedplate (mm) | 432 | 502 | 559 | 603 | 711 | 832 | 965 | 965 |

| C Bedplate (mm) | 610 | 711 | 787 | 914 | 1016 | 1092 | 1168 | 1270 |

| D Bedplate (mm) | 165 | 203 | 203 | 235 | 260 | 343 | - | - |

| E Hole in Bed (mm) | 305 | 356 | 406 | 445 | 508 | 559 | 610 | 660 |

| F Hole in Bed (mm) | 229 | 354 | 279 | 305 | 406 | 483 | 559 | 610 |

| G Hole in Bed (mm) | 279 | 305 | 330 | 406 | 457 | 546 | - | - |

| H Slide Face (mm) | 343 | 394 | 457 | 457 | 737 | 914 | 965 | 1143 |

| I Slide Face (mm) | 241 | 273 | 324 | 394 | 635 | 762 | 864 | - |

| J Slide Face (mm) | 140 | 184 | 229 | 229 | 305 | 318 | 330 | 381 |

| K Slide Face (mm) | 254 | 318 | 385 | 385 | 559 | 635 | 660 | 762 |

| L Slide Face (mm) | - | - | - | - | 203 | 254 | 279 | - |

| M Sliding Face Dia (mm) | 17 | 21 | 27 | 27 | 25 | 29 | 29 | 35 |

| N Sliding Face Dia (mm) | 51 | 51 | 51 | 51 | 64 | 64 | 64 | 64 |

| O Sliding Face Deep (mm) | 152 | 178 | 178 | 178 | 191 | 203 | 203 | - |

| P Slots for T bolt - Dia (mm) | 19 | 19 | 22 | 22 | 22 | 22 | 29 | 32 |

| Passage through back (mm) | 279 | 311 | 356 | 368 | 546 | 651 | 660 | 711 |

| Throat Depth (mm) | 216 | 241 | 273 | 292 | 349 | 381 | 457 | 457 |

| Overall - Height (mm) | 2388 | 2439 | 2616 | 2667 | 3226 | 3505 | 4064 | 4648 |

| Front to Back (mm) | 1425 | 1473 | 1702 | 1804 | 2210 | 2439 | 2667 | 2845 |

| Left to Right (mm) | 1220 | 1346 | 1473 / 1524 | 1473 / 1550 | 1854 | 2210 | 2362 | 2464 |

| Floor - Bed (mm) | 813 | 840 | 864 | 864 | 813 | 864 | 864 | 875 |

| Approximat Weight in tonnes. | 3 | 4 / 4.5 | 6.25 / 7 | 7 / 7.75 | 11 / 11.75 | 15.25 | 24 | 25 |