Group Rhodes has a successful history of manufacturing Hot Platen Presses utilising various heating mediums such as Steam, Water, Thermal Fluid, and Electrical. The heating system depends on the maximum temperature and accuracy requirements.

The platens are manufactured from solid steel plate as opposed to fabricated construction, to ensure a high resistance to distortion and thermal shock. Each press includes platens that are supported by insulation boards, which have excellent thermal properties, together with water cooling plates which have a serpentine flow path of cooling water to eliminate residual heat being transferred into the press structure.

The platens, which can be manufactured up to 10 Metres long and 2.5 metres wide, are accurately machined and ground flat and parallel, to within 0.03 mm/metre to offer an extremely accurate platform for supporting the tooling or the product.

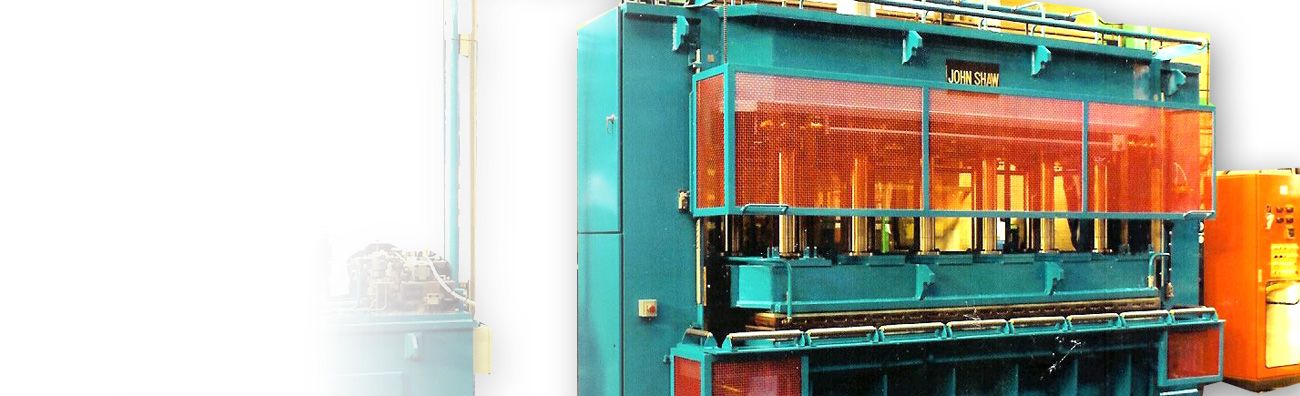

Group Rhodes has manufactured many Multi Daylight Hot Platen Presses, some with up to 20 Press Daylights.

The Benefits

Group Rhodes composite moulding presses offer manufacturers an extremely accurate temperature and flatness platform to accept tooling or flat panel products.

Typical Products Produced

Helicopter rotor blades, aircraft floor panels, bulk head panels, interior honeycomb structural panels and aircraft engine casings.