Rhodes stretch forming machines have the ability to form aluminium, stainless steel and titanium alloys. The process involves a component sheet being stretched to its yield condition and then draped over a male forming tool. Stretch formed components offer an accurate finished profile with minimal spring back.

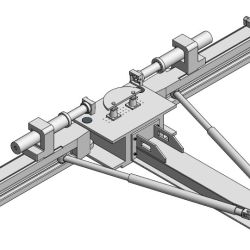

A straight component section is positioned on the machine table located between two opposing hydraulic gripper jaws, which are slide mounted on horizontal pivot arms. Pre-determined tension is applied to the component between the gripper jaws, prior to the pivot arms (driven by hydraulic cylinders) swinging backwards, thus wrapping the component over the fixed former. The machine is controlled by a Rhodes HMI which is run using the latest Siemens software.

The Benefits

Reduced spring back enabling accurate profiles to be manufactured.

Typical Products Produced

Aircraft fuselage and wing panels