The Rhodes KJX range of Horizontal Impact Extrusion Presses are designed for the production of non-ferrous (recyclable) tubes and cans such as Battery cases, Toothpaste tubes, Cosmetics, Machine Pharmaceutical Tubes and Aerosol Cans. Press capacity ranges from 5 to 1000 tonnes, to enable the correct machine to be selected for each application.

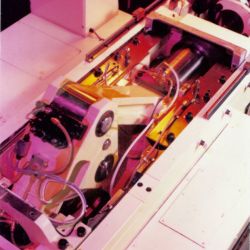

Group Rhodes manufacture a range of KJX presses designed to eliminate the out-of-balance forces, or convert them from the horizontal to the vertical plane, in order to ensure smooth running at high speeds. This is achieved with a radical new linkage design and dual balancing system, which reduces stress and shock loads within the press. Furthermore, to ensure smooth running and minimum vibration, the crankshaft and knuckle linkage have been dynamically balanced using the latest Computer Aided Design technology and now operate within a rigid, fully-stress relieved, one piece steel fabricated frame.

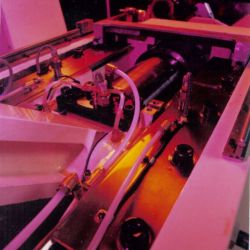

To meet new production demands, non-ferrous calots are automatically orientated before being fed down the chute in front of the tool to be backward extruded. After extrusion, the can or tube is stripped from the punch onto a continuous conveyor, which in turn supplies the complimentary machinery developed to run at the new high speed.

Additional features include:

- An AC variable drive motor to ensure the automatic speed changes are performed quickly and safely.

- An Ergonomically redesigned toolspace area with improved accessibility.

- Precision engineered double helical gears rotating in a sealed oil bath.

- A Can Take-Off System, which is independently adjustable for timing, and protected by an overload clutch.

- The highly successful 'Ortlinghaus' combined pneumatic friction clutch and brake unit.

- A fully automatic 'full flow' recirculating oil lubrication system using internally machined oilways, thereby reducing the need for vulnerable flexible pipework.

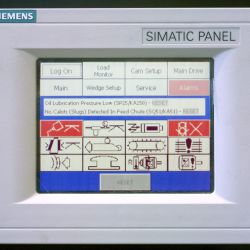

- CNC or PLC Technology

- Motorised slide adjustment

- Bowl feeders

- Feed system

- Hopper elevators

- Ejectors and Compensators

- Soundproof Enclosures

| Model No | Stroke (mm) | A |

|---|---|---|

| KJX 25 | 254 | 25 |

| KJX 35 | 300 | 30 |

| KJX 35S | 300 | 30 |

| KJX 50 | 330 | 35 |

| KJX 50S | 314 | 35 |

| KJX 50L | 381 | 35 |

| KJX 63 | 381 | 38 |

| KJX 63S | 280 | 38 |

| KJX63L | 457 | 38 |

| KJX 75 | 457 | 40 |

| KJX 90 | 520 | 45 |

| KJX 120 | 585 | 50 |

| Example | ||

| Press model No. KJX 50 40 mm Diameter collapsable tube Total die depth - 28 mm Maximum overall extruded length . = 330 - (28 + 35 + 40) . = 330 - 103 . = 227 |

||

| KJX RANGE | ZINC | ALUMINIUM | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Model Ref: (note 1) | KJX | KJX | KJX | KJX | KJX | KJX | KJX | KJX | |

| 24 | 32 | 8 | 25 | 35 | 35S | 50 | 50L | ||

| Pressure Capacity (Tons) | 60 | 120 | 5 | 60 | 100 | 100 | 160 | 160 | |

| Rating from B.D.C (mm) (note 2) | 5 | 7 | 4.5 | 4.5 | 4.5 | 9.7 | 4.5 | 4.5 | |

| Stroke (mm) | 130 | 172 | 102 | 254 | 300 | 300 | 330 | 381 | |

| Speed (spm) | 150/180 | 150/280 | 150 | 80/170 | 100/200 | 100/200 | 80/150 | 60/120 | |

| Maximum Ø with 0.12mm Wall (A1.) | \ | \ | 8 | 25 | 35 | \ | 50 | 50 | |

| Maximum Ø with 0.30mm Wall (A1.) | \ | \ | 10 | 30 | 42 | 40 | 56 | 56 | |

| Maximum Ø with 0.30mm Wall (Zinc.) | 24 mm | 32 mm | \ | \ | \ | \ | \ | \ | |

| Drive Motor (kW) | 18.75 | 3.7 | 1.1 | 10 | 17.5 | 30 | 40 | 40 | |

| Press Weight (Kg) | 5,800 | 10,000 | 1,000 | 6,000 | 9,500 | 10,200 | 9,500 | 10,000 | |

| OVERALL SIZES (MM) (note 3) | Length | 2100 | 2770 | 1375 | 2870 | 3340 | 3350 | 3470 | 3760 |

| Width | 1380 | 1730 | 610 | 1310 | 1980 | 2000 | 2310 | 2310 | |

| Height | 1300 | 1650 | 690 | 1520 | 1550 | 1550 | 1750 | 1780 | |

| KJX RANGE | ALUMINIUM | |||||||

|---|---|---|---|---|---|---|---|---|

| Model Ref: (note 1) | KJX | KJX | KJX | KJX | KJX | KJX | KJX | |

| 50S | 63 | 63L | 63S | 75 | 90 | 120 | ||

| Pressure Capacity (Tons) | 200 | 325 | 325 | 325 | 400 | 650 | 1000 | |

| Rating from B.D.C (mm) (note 2) | 7 | 4.5 | 4.5 | 8 | 10 | 25 | 35 | |

| Stroke (mm) | 314 | 381 | 457 | 280 | 457 | 520 | 585 | |

| Speed (spm) | 80/170 | 60/120 | 40/80 | 80/170 | 40/80 | 25/50 | 30 | |

| Maximum Ø with 0.12mm Wall (A1.) | 50 | 63 | 63 | 60 | 75 | 90 | 110 | |

| Maximum Ø with 0.30mm Wall (A1.) | 55 | 73 | 73 | 70 | 87 | 100 | 130 | |

| Maximum Ø with 0.30mm Wall (Zinc.) | \ | \ | \ | \ | \ | \ | \ | |

| Drive Motor (kW) | 48 | 65 | 65 | 80 | 70 | 80 | 120 | |

| Press Weight (Kg) | 12,400 | 19,000 | 21,000 | 23,000 | 40,000 | 68,000 | 85,000 | |

| OVERALL SIZES (MM) (note 3) | Length | 3650 | 4200 | 4650 | 4000 | 5100 | 5950 | 6550 |

| Width | 2090 | 2170 | 2170 | 2610 | 3050 | 3500 | 3950 | |

| Height | 1830 | 1920 | 1920 | 2170 | 2400 | 2850 | 2960 | |

Notes:

1 This specification table is provided as a guide only. Machine speed and capacity requirements vary significantly between specific applications. Please contact our technical sales department for further advice on model selection.

3 Rating from Bottom Dead Centre (B.D.C) is the distance (mm) through which maximum pressure capacity can be applied.

4 Overall press sizes are approximate.