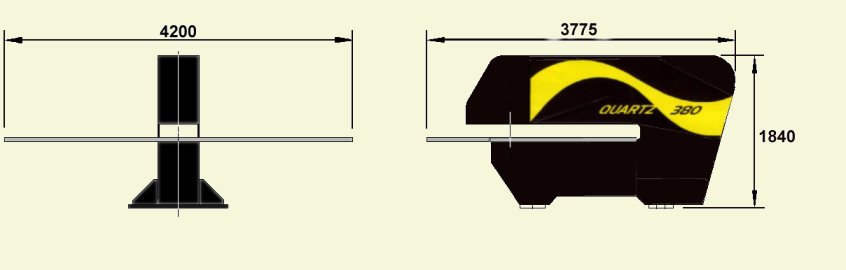

The Quartz is the latest CNC Punching Machine from Rhodes. Built at the Wakefield factory, Quartz offers a rigid fabricated frame capable of withstanding the rigors of rapid punching operations, yet fully integrated hydraulics keep the Quartz footprint to a minimum.

A dedicated CNC control system ensures unrivalled production flexibility complementing the extensive use of lightweight materials to generate exceptional performance figures.

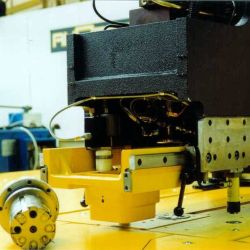

The compact hydraulic punching unit, with valves mounted directly on to the hydraulic cylinder, offers dramatic improvements in switching times and operational functionality without the need for large electric motors and flywheels. This space saving design greatly simplifies transportation, installation and relocation. The rapid yet soft switching characteristics are provided by the Rhodes Adaptive Motion (RAM) workstation via pilot operated directional valves. Maximum hydraulic power is available throughout the full length of the stroke making Quartz ideal for forming operations as well as notching and punching.

'State-of-the-Art' linear motors, driving low inertia aluminium beams provide fast accelerations, rapid speeds and accurate positioning of the work piece. Linear motors, being non-contact in operation are virtually maintenance free and neither require lubrication nor are they subject to backlash, timing belt inaccuracies or mechanical losses associated with traditional ballscrews or rack and pinion assemblies.

Additional features include:

Auto Repositioning - Hydraulic cylinders clamp the component rigidly to allow accurate repositioning of the work holding clamps and ensure full sheet utilisation.

Tooling - The machine is designed to accept standard thick or thin turret type punch press tooling up to 88.9mm diameter, other punch press tooling systems may also be accommodated. Rigidly guided tools accurately located on precision keyways are quickly changed via a simple slide out arrangement before being mechanically locked back in position with a cam lock assembly. Multitool units can be used to improve production rates by reducing tool change times.

CNC Control - Behind the dedicated 17" touch screen control of the Quartz fascia lies the latest technology in motion systems. The Rhodes Adaptive Motion (RAM) workstation utilises the performance platform of the Intel Pentium Processor to run Windows NT Software specifically written for the Quartz Punch Press. Digital control of each axis eliminates the delays experienced with analogue systems, contributing to improved performance and accuracy. Extensive on board program storage also ensures that the machine can tackle high volumes of complex punching programmes.

An internal modem facilitates remote diagnostic monitoring and an error logging feature allows press information to be exported to standard spread sheets, even during production! Programming of Quartz can be carried out either at the machine itself or off-line before being down loaded by disc or PC interface and displayed graphically at the machine control.

Additional features of the RAM control system include, full graphical part representation, real time graphical update of machine progress, error message page with diagnostic help pages and M.D.I. program editing. A material database, fully programmable tools, a tool library and a production logging facility are also provided as standard.

QUARTZ 400 HS Specification

| Feature | Units | Value |

|---|---|---|

| Punching Capacity | Tonnes | 20 |

| ‘X’ Axis Travel | mm | 2000 |

| ‘Y’ Axis Travel | mm | 1000 |

| Hit Rate-Nibbling | HPM | 400 |

| Hit Rate @ 8 mm Stroke | HPM | 380 |

| Hit Rate @ 25mm Pitch | HPM | 200 |

| Single Axis Speed | m/min | 40 |

| Combined Axis Speed | m/min | 56 |

| Maximum Punch Size | mm (dia) | 88.9 |

| Multitool Nibbling | Mm (mild steel) | 3 |

| Max Material Thickness | mm (Mild Steel) | 6 |

| Maximum Sheet Weight | Kg | 100 |

| Positioning Accuracy | mm | ± .1 |

| Power Required | Kva | 22 |

| Machine Weight | Kg | 7000 |