One of Wakefield's Longest Established Manufacturers Celebrates 200th Anniversary

Group Rhodes, the Wakefield-based manufacturer of original equipment for the metalforming, composites, heavy ceramic and material handling sectors, has marked its 200th anniversary by revealing its recent exciting facility expansion.

The company has expanded its operations into a brand-new 25,000-square-foot premises adjacent to its manufacturing facility in Wakefield, West Yorkshire. The extended factory will allow Group Rhodes to enhance its operations with new spares and storage space, enabling it to be more responsive to customer requirements.

The news comes just weeks after Group Rhodes announced it had appointed 16 new staff across its Rhodes Interform, BJD Crushers and Craven Fawcett businesses. Part of its growth success is due to Group Rhodes acquiring BJD (British Jeffrey Diamond) Crushers, which manufactures and supplies a wide variety of material processing equipment including high-capacity crushers designed to control product size. Group Rhodes also attributes its growth to securing major new international contracts alongside significant domestic sales to companies such as Ibstock plc, Zentia and Cascade Manufacturing.

Mark Ridgway, OBE DL, Chief Executive of Group Rhodes, explains "This is a really exciting time for our business, as we celebrate our 200th anniversary and expand into our new premises. Since 1824, when our company started out mechanising the tinker's (tinsmith) trade, we have remained dedicated to quality in both manufacture and service. Over the years, we have established our reputation as a quality original equipment manufacturer for many industries, including metal fabrication, aerospace and clay preparation. With our expanded factory we will be in an even stronger position to take advantage of both UK and international business opportunities. It is fantastic to report that our business is going from strength to strength and we are looking forward to celebrating this significant milestone in our history."

Group Rhodes manufactures and markets its state-of-the-art machinery from its factory in West Yorkshire, which it sells to both the UK and global markets. The company has extensive capabilities including the design, development and manufacture of bespoke equipment and the provision of complete turnkey solutions. BJD Crushers, Craven Fawcett and Hallamshire Engineering Services manufacture machinery and spare parts for the aggregates, heavy clay and material handling sectors, whereas Rhodes Interform focuses on the design and manufacture of machinery to serve the advanced metal and composite forming industries, with a particular focus on the aerospace sector.

If you want to find out more information about Group Rhodes, please visit the website https://www.grouprhodes.co.uk/, call us at +44 (0) 1924 371161. Alternatively, follow the company on LinkedIn.

Brief history of Group Rhodes

In 1824: Joseph Rhodes, a young engineer designed and built his first machine workshop in Wakefield. The 19th Century was a period of great invention with a wide variety of Rhodes ' sheet metal working machines produced. A catalogue from 1895 shows the value of Rhodes presses in making tins, oil cans and brass goods for the home.

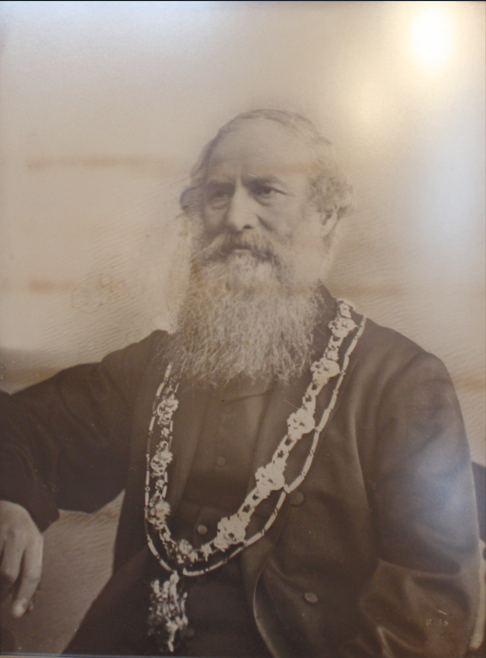

In the second half of the 19th Century, Joseph Rhodes' two sons, William and George, joined the business. The company had moved to new premises on Ings Road in Wakefield and enjoyed a period of expansion. Joseph Rhodes & Sons became a limited company in 1899 and William and George managed the firm jointly until 1900, when George left to set up his own business. William Rhodes also played a part in local politics, first becoming a councillor in 1894 and Mayor of Wakefield in 1903.

William's son Charles took his place at the head of the company. Under Charles and his Managing Director Harry Ridgway, the company developed machines to meet the Government's requirements during two world wars. Harry, who joined the business as Chief Draughtsman in 1912, was the grandfather of the current Chief Executive, Mark Ridgway.

In 1921, the company moved from The Ings to the site where it was based until recently, Belle Vue in Wakefield. During the Second World War, Rhodes presses were sent overseas to India, Africa and the Middle East.

In the 1950s the company, which had an export office since 1910 in Paris, began an export drive, which was assisted by Harry Ridgway's invention of the world's first commercial hydraulic shear and press brake, patented in 1943. Harry Ridgway was appointed Managing Director from 1946 until he retired in 1967.

By the mid-1950s, the company had an extensive product range of over 1,000 types of machines for the sheet metal working industry. The British Machine Tool Engineering Magazine in 1954 reported such a range was 'the largest variety made by a firm in the world." In 1959, Charles Rhodes died and in 1961, the company Joseph Rhodes was acquired by Lindustries, however leadership continued under the managing director Harry Ridgway. Harry continued to guide the company until its retirement in 1967, after 50 years with the firm.

Lindustries was then subject to a takeover bid by Hanson Trust plc in 1979, so Joseph Rhodes Ltd became part of an enlarged Hanson group. The recession of the 1980s diminished the returns generated by the company and in 1984 the Hanson Board agreed to a Management Buy-Out by Ian Ridgway, son of Harry Ridgway who was Commercial Director and by Production Director John Blacker. Once under private ownership, the company was flexible enough to re-focus on the design of high technology products.

In 1994, John Blaker retired and the business was then headed solely by Chairman and Managing Director Ian Ridgway. The new management team made several acquisitions of synergistic metalforming companies in the mid-1990s, including HMW, Bentley and Dualform. In 2000, Ian Ridgway's son Mark Ridgway OBE, DL, who joined the company in 1985, became Managing Director, with Ian Ridgway continuing as Chairman.

In 1994, John Blaker retired and the business was then headed solely by Chairman and Managing Director Ian Ridgway. The new management team made several acquisitions of synergistic metalforming companies in the mid-1990s, including HMW, Bentley and Dualform. In 2000, Ian Ridgway's son Mark Ridgway OBE, DL, who joined the company in 1985, became Managing Director, with Ian Ridgway continuing as Chairman.

Group Rhodes came into being in 2004 following the acquisition of Craven Fawcett a pioneer in the field of Clayworking machinery. More recent additions to the Group include Beauford Engineers, Fielding and Platt, John Shaw, Chester Hydraulics, Henry Berry, Hallamshire Engineering Services and Atkin Automation.

In 2010, Group Rhodes won the Queen's Award for Enterprise (Innovation), and the company won the award again in 2012 for International Trade. In 2011, the group's Chief Executive Mark Ridgway was awarded the OBE for services to industry.

In August 2016, the business underwent a major restructure, with three of its associated companies Rhodes Interform Ltd, Craven Fawcett Ltd and Hallamshire Engineering Services Ltd operating under a new parent/subsidiary structure headed by parent company Group Rhodes Ltd. The consolidation of the three main businesses under Group Rhodes enabled them to share resources and technical expertise and lift the business onto a more profitable operating platform.

In 2018, Crescent Machinery joined Rhodes Interform focusing on both machine tool servicing and equipment necessary for health and safety accreditation and in 2023 Group Rhodes welcomed the latest company to its family with the acquisition of BJD Crushers, previously British Jeffrey Diamond. This acquisition brought BJD back to its Wakefield roots, where the company first began trading in 1897.

In 2024, Group Rhodes was awarded global patents for its Superplastic Forming and Diffusion Bonding technology. (for the lightweighting of aircraft.)