£7.1 Million Research & Development Project

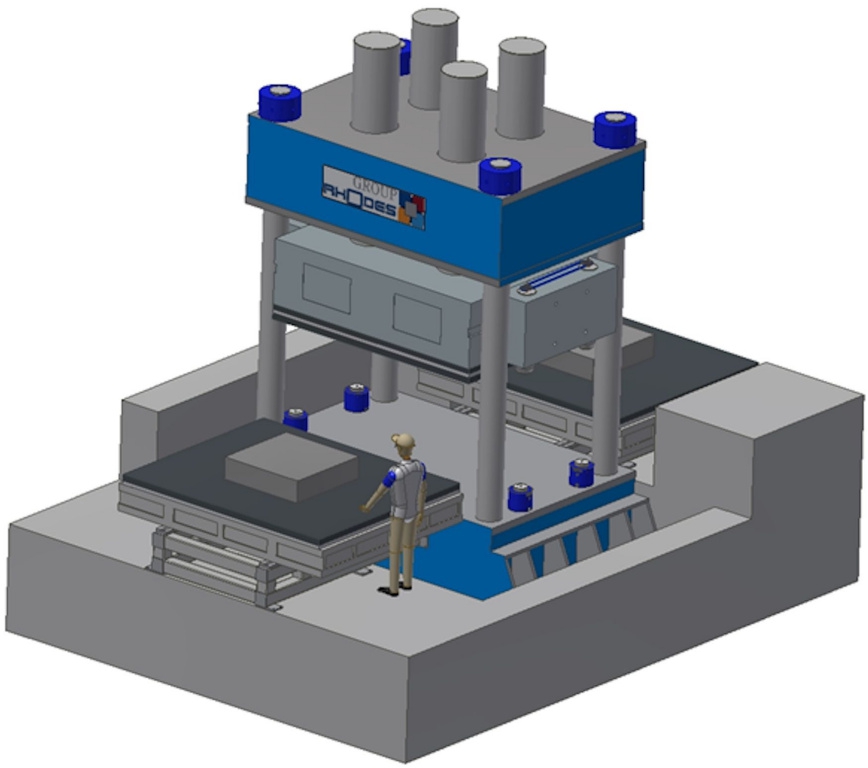

Group Rhodes is a partner company in a consortium seeking to enhance capability within the UK automotive supply chain to manufacture composite components in medium to high volumes, at affordable costs, by connecting the key functions of material supply, design and manufacturing.

Group Rhodes is a partner company in a consortium seeking to enhance capability within the UK automotive supply chain to manufacture composite components in medium to high volumes, at affordable costs, by connecting the key functions of material supply, design and manufacturing.

Known as the Lightweighting Excellence Programme (LX), it involves a strategic co-operation between Group Rhodes, Sigmatex, Axillium Research, Caparo Advanced Composites, Cranfield University, Engenuity, Expert Tooling & Automation, Granta Design, LMAT, Surface Generation and Tilsatec.

The LX consortium is working with three UK-based automotive OEMs in order to achieve vehicle weight reduction. Bentley Motors, Emerald Automotive and Nissan are working closely with the LX partners on the provision of three technical use cases with realistic commercial potential.

The LX Programme was officially launched at Advanced Engineering UK 2015, having received an Unconditional Offer Letter (UCOL) confirming funds of £3.8M from the Advanced Manufacturing Supply Chain Initiative (AMSCI) programme via Finance Birmingham.

AMSCI was set up by the UK Government to help existing UK supply chains grow and achieve world-class standards while encouraging major new suppliers to set up manufacturing in the UK.

A total project value of £7.15M of joint funding from AMSCI and industry will support the creation of 238 new jobs and safeguard 144 existing jobs between 2015 and 2021.

OEMs are now working on weight reduction to ensure compliance with stricter emissions standards. However, as the amount of technology demanded in today’s passenger vehicles increases, so does the overall weight. Composite materials allow OEMs to counteract this effect through lightweighting and part consolidation, while maintaining structural integrity.

Many UK-based automotive OEMs have expressed interest to source a higher percentage of their composite components from within the UK. The LX Programme addresses these desires by consolidating all elements of the supply chain to produce demonstrator components to showcase UK capability.

By the conclusion of the LX Programme in 2017, the consortium will have established the design capability and processes required to produce structural, semi-structural and Class A surface finished components in significant volumes.

The three OEMs are working together with the LX consortium on the following ‘Use Cases’:

Bentley Motors – Door Inner Structure

Bentley has offered as a use-case the challenge of replacing a structural Door-Inner sub-assembly, currently made of numerous metallic parts, with a simplified carbon composite assembly. The Door-Inner assembly anchors the door’s anti-intrusion beams and mountings for numerous components such as electric window motors, window frame guides and exterior skin connection. Using composite materials, the LX consortium aims to produce a lightweight concept that reduces the number of parts used, while retaining strength, stiffness and crash integrity. This weight reduction could ultimately enable increased functionality that is sometimes prohibitive due to the weight of the existing metallic structures.

Emerald Automotive – exterior body panels

Emerald Automotive is developing a lightweight commercial vehicle that could utilise thermoplastic exterior body panels in the future. They are expected to achieve a high quality Class A surface finish that is lightweight, durable and dent resistant. The project outcome will see the LX consortium members working together in a robust supply chain to create a UK-based production facility that uses automated technology and thermoplastic composite moulding know-how to ensure an uninterrupted supply of Class A body panels to help Emerald Automotive meet demand for what will become a popular global vehicle. When the LX consortium has proven rate, process, quality and price, component production numbers are anticipated to be in low to medium volumes.

Nissan – structural component

Nissan believes that significant lightening of the weight of a passenger vehicle by replacing an existing metallic body structure with lightweight carbon composite is a future requirement. One of the most difficult candidate parts for manufacturing in carbon composites could be a structural floor component which Nissan is offering the LX programme for development. The first run of prototypes will be produced in early 2016 as proof of concept, showing high volume manufacturing methodology and processes ready for future full-scale production. The key challenges for the LX partners to overcome are producing a floor that is significantly lighter than the existing metallic part, at a price that is comparable with the existing metallic component it replaces, while maintaining consistent high quality, structural performance and just-in-time delivery to the production line.

Group Rhodes key player in producing lighter more fuel efficient cars.

http://www.grouprhodes.co.uk/news/rhodes/7-1-million-research-development-project